Prosthetic knees range from simple, purely mechanical devices to sophisticated microprocessor-controlled systems. A Hydraulic prosthetic knee consists of a hydraulic cylinder in a single axis or polycentric knee design. Valves of the hydraulic cylinder can be adjusted to tune the swing flexion and extension as per the amputee’s desired walking speed.

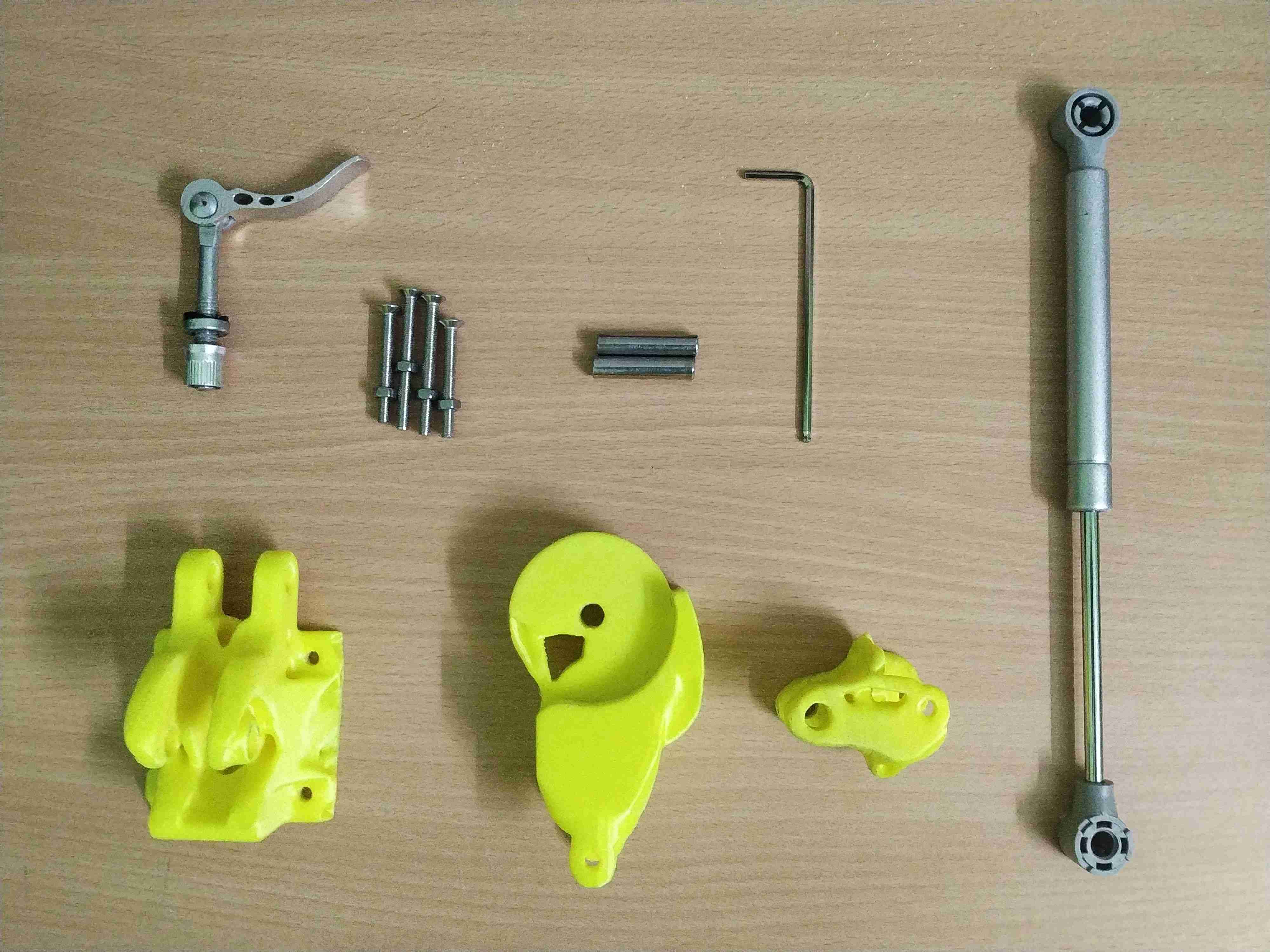

Components

| 3D printed components | 3 | 235g PLA/ABS |

| Hydraulic gas spring | 1 | $15 |

| Quick release clamp | 1 | $7 |

| 50mm M5 SS Nuts & Bolts | 4 | $3 |

| 50mm M8 SS Nuts & Bolts or 8mm SS Shaft | 2 | $3 |

| Total | $28 |

*The links provided are for reference purposes only.

3D Printing

The settings used for each of the three 3D printed components are listed below,

| Parameter | Comp 1 | Comp 2 | Comp 3 |

| Nozzle diameter | 0.4mm | 0.4mm | 0.4mm |

| Layer height | 0.2mm | 0.2mm | 0.2mm |

| Infill | 80% | 80% | 80% |

| Mass | 94g | 109g | 32g |

| Duration | 11hrs 18mins | 13hrs 7mins | 4hrs 57mins |

STL files can be downloaded from the repository. Each 3D printed component has been optimized for minimal compliance under a specified volume fraction.

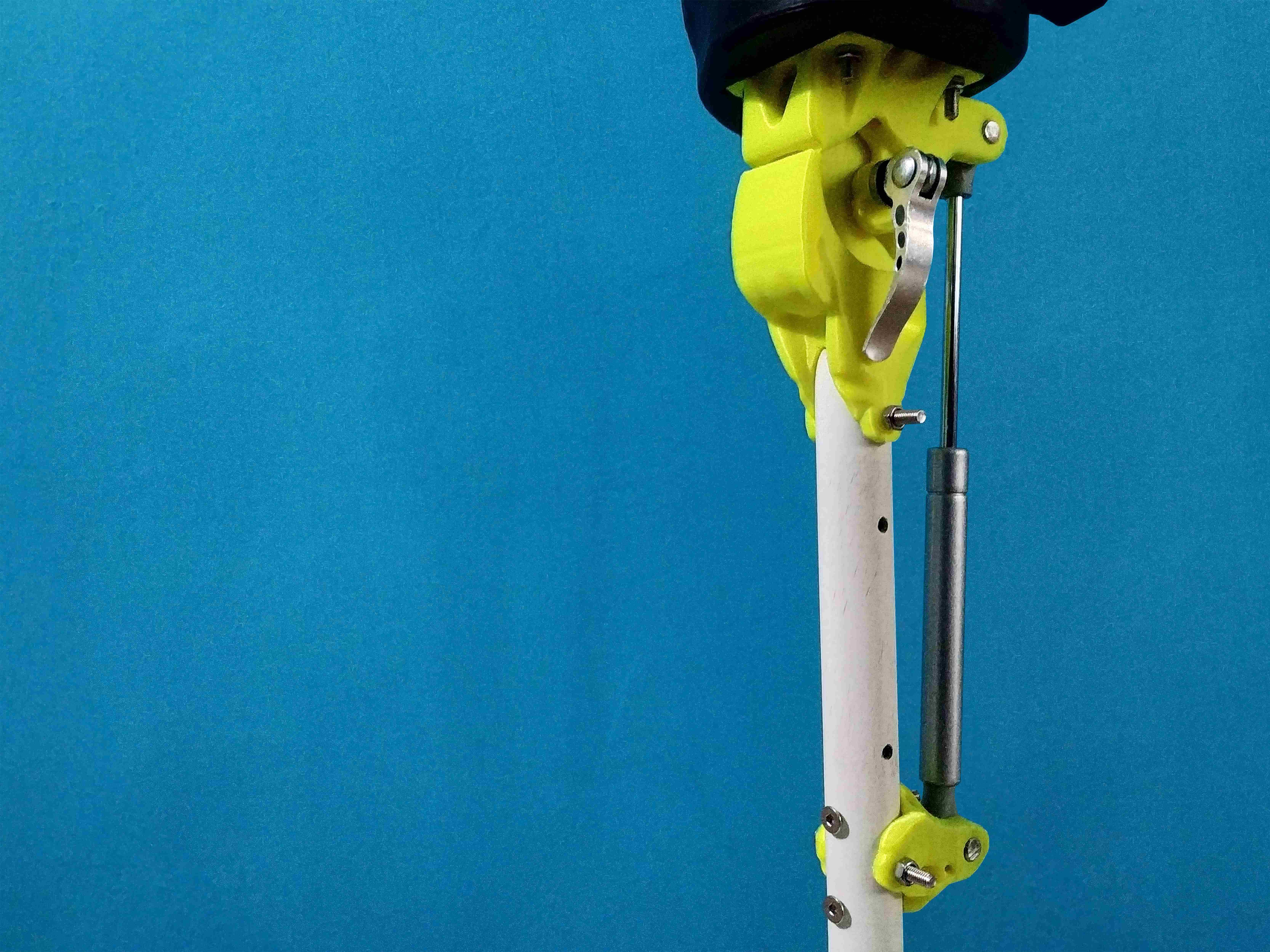

Assembly

The entire assembly process can be broken down into three steps,

- Assemble components

1and2concentrically, ensure that there is no friction between the 3D printed components. - Lock these two components in-place with the quick-release clamp to make a sub-assembly.

- Use two

M8bolts or8mmSS shafts to mount the hydraulic gas spring such that it connects the sub-assembly to component three.

Hydraulic gas springs are available at a range of pressure values. Inexpensive hydraulic gas springs lack the functionality to be able to adjust the valves to tune the swing flexion and extension. If this functionality is much desired, Rear shocks found on mountain bikes can be used instead of inexpensive hydraulic gas springs. Both rebound and compression can be adjusted. Tuning the pressure difference between main air chamber and negative air chamber requires precision.

*The showcased design is not meant to be used with a rear shock.

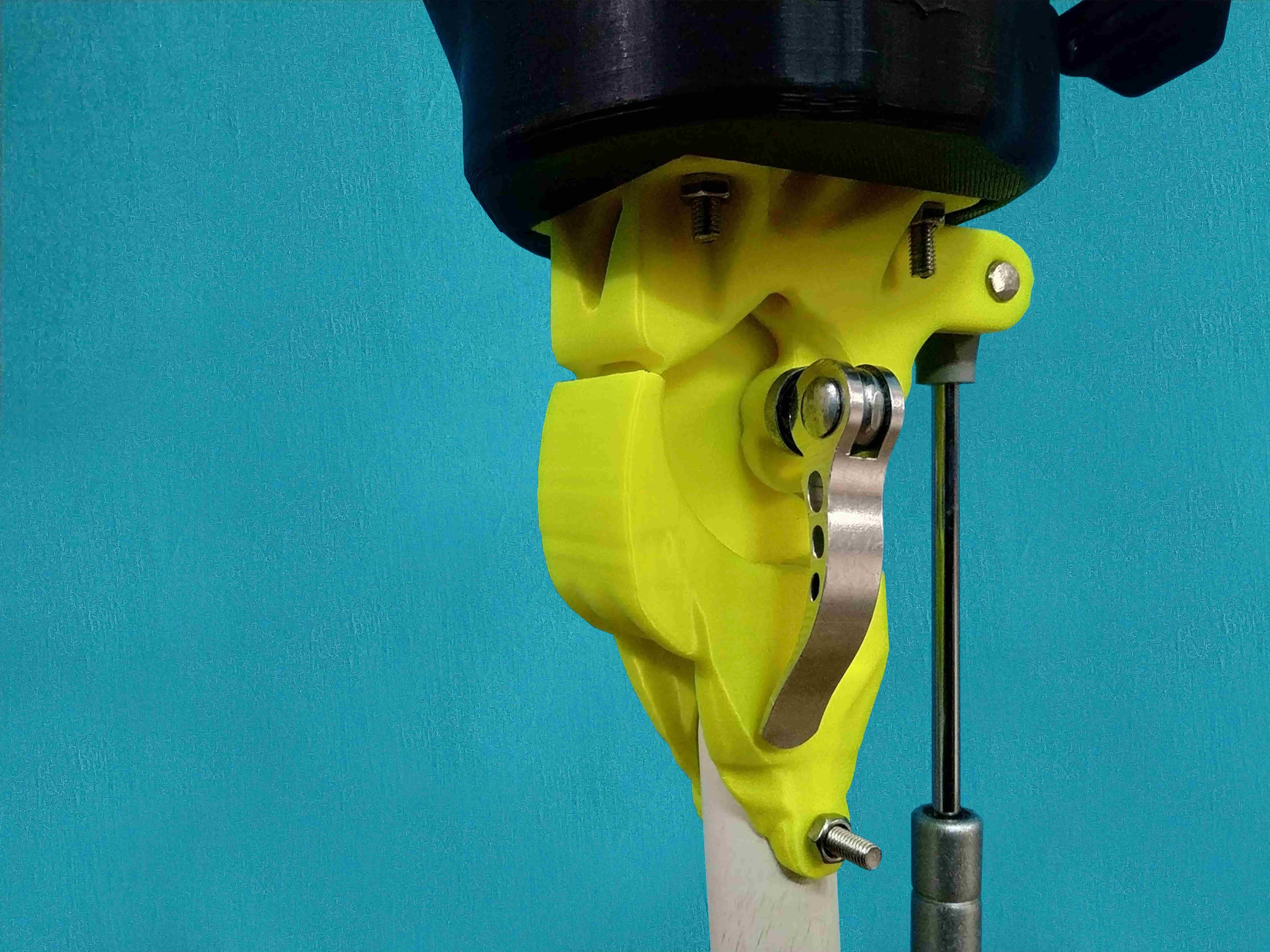

Friction control

In addition to tuning the hydraulic cylinder as per the amputee’s weight and walking speed, the quick-release clamp can be adjusted to increase or decrease the friction between components 1 and 2, this significantly modifies the knee joint’s dynamic behaviour.

The developed prosthetic knee costs $28 and 235g of PLA/ABS filament for 3D printing.